Blog

How to Produce Perforated Metal Sheets

How to Produce Perforated Metal Sheets: A Step-by-Step Guide

Producing perforated metal sheets involves a series of precise and well-coordinated processes. Here’s a breakdown of the steps involved:

1. Material Selection

Choosing the Metal: The process begins with selecting the appropriate metal based on the intended application. Common materials include stainless steel, aluminum, mild steel, and copper. The choice of metal affects the sheet’s durability, appearance, and resistance to corrosion.

2. Cutting the Metal Sheet

Sheet Preparation: Large metal rolls or pre-cut sheets are prepared for the perforation process. These sheets are typically cut to the required dimensions before perforation begins.

3. Perforation Process

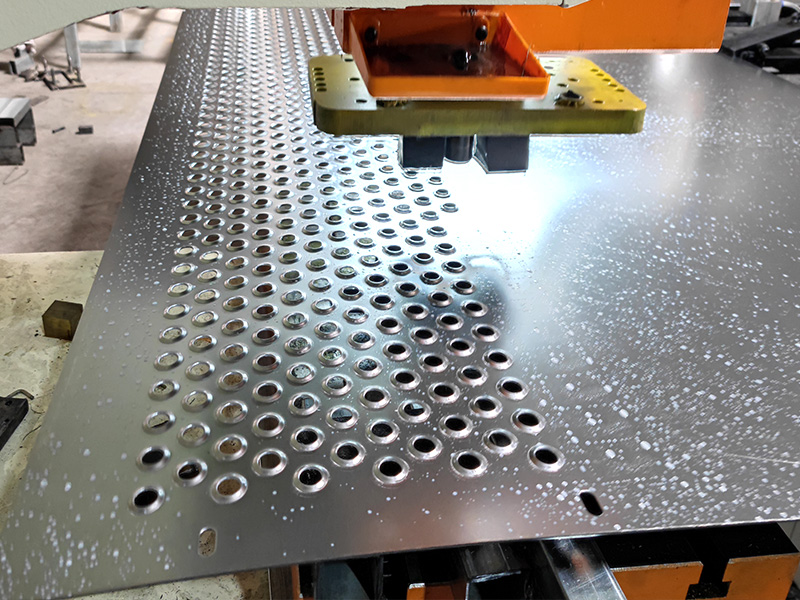

Punching Machines: The metal sheet is fed into a perforating machine equipped with a die and punch. The punch forces the metal through the die, creating holes or patterns.

Patterns and Hole Shapes: The die design determines the pattern and shape of the perforations, which can range from simple round holes to complex shapes like hexagons, squares, or decorative designs.

4. Flattening

Leveling the Sheet: After perforation, the sheet may become slightly deformed or warped. The sheet is passed through a leveling machine to flatten it and ensure uniform thickness.

5. Cutting to Size

Final Dimensions: The perforated metal sheet is cut to its final size using shearing or laser cutting, depending on the required precision. This step is crucial for meeting specific dimensions and tolerances.

6. Finishing

Surface Treatment: The sheet may undergo various finishing processes to enhance its appearance and durability. Common finishing techniques include:

Deburring: Removing sharp edges or burrs created during perforation.

Coating: Applying protective coatings such as powder coating, anodizing, or galvanizing to enhance corrosion resistance and aesthetics.

Polishing: Polishing the surface to achieve a smooth finish, often used for decorative applications.

7. Quality Control

Inspection: The final product is inspected for defects, such as uneven holes, burrs, or warping. Quality control ensures the perforated sheet meets the required specifications and industry standards.

8. Packaging and Shipping

Packaging: The finished perforated metal sheets are carefully packaged to prevent damage during transportation. This may include stacking, wrapping with protective materials, and securing on pallets or in crates.

Shipping: The packaged sheets are then shipped to customers or distribution centers, ready for use in various applications.

Applications of Perforated Metal Sheets

Perforated metal sheets are used in a wide range of industries, including construction, automotive, architecture, filtration, and acoustics. Their versatility and durability make them a popular choice for numerous applications.

By following these steps, manufacturers produce high-quality perforated metal sheets that meet the demands of different industries and applications.

RELATED NEWS

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Mr.Zhou

Phone: 86-13385821144

E-mail: Peter@leadermesh.com

Whatsapp:86-13385821144

Add: Anping County Wire Mesh Industrial Park, Hengshui City, Hebei Province